Stripping of enameled copper wire

we have successfully stripped various enameled copper wires with a 20W blue diode laser from our BlueLas product series at a wavelength of 450nm so that they can then be successfully connected electrically by soldering.

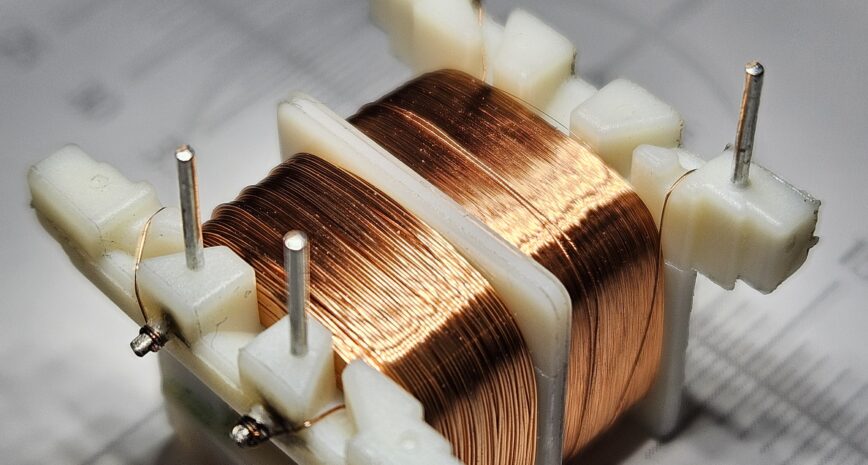

wound coil, both with solid copper wire and with stranded wire structure

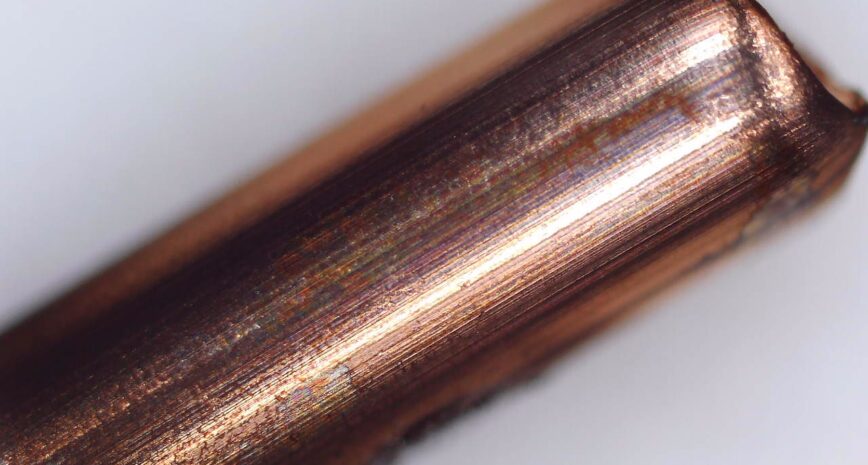

In preparation, various laser shooting tests were carried out in advance on the copper wires

The starting point for our laser stripping was the already specified copper wire winding around the four coil pins

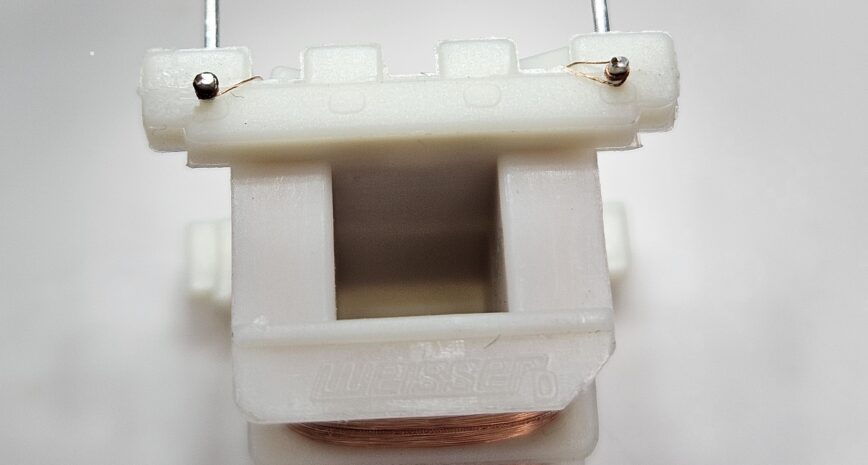

After laser shooting before cleaning and soldering

Coil with successfully soldered pin (left)

Solid enameled copper wire, stripped by a 50W BlueLas laser diode and subsequent cleaning

If you have any questions about this process or other applications, please contact our sales department

Thank you very much!