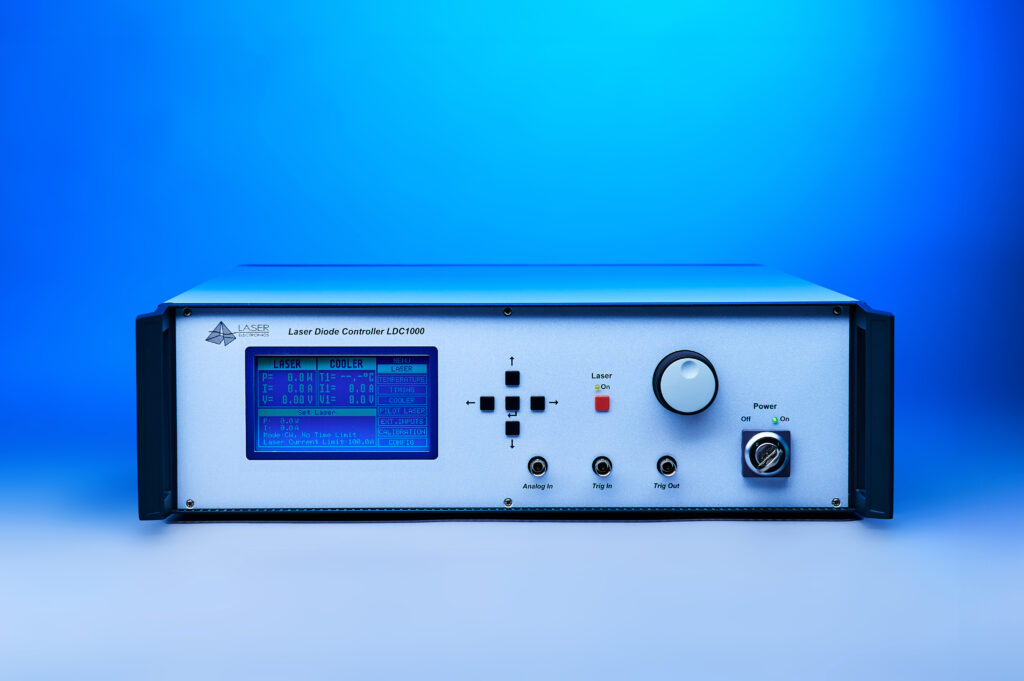

Laser Diode Controller LDC1000

Laser Diode Driver with TEC-Driver

Features

- 600, 1000 or 1.500W laser diode driver

- Up to 300A laser diode current

- Up to 60V laser diode voltage

- CW and pulse operation

- Microprocessor control

- Graphical display

- Menu-driven interface

- Extern analogue modulation

- External trigger input and -output

- Interlock function

- RS232 PC Interface

- PI temperature controller

- Integrated TEC driver 300 or 600W

- Second TEC driver 15W optional

- Up to 48V / 13A bipolar

Applications

- High power laser diode control

- Pumping solid state lasers

- Laser diode Burn-In and test station

- Material processing

- Illumination

- General purpose laboratory instrument

Description

The Model LDC1000 conveniently offer both laser diode current and temperature control in the same instrument. The current source provides CW or pulsed output currents to drive high power laser diodes, laser arrays and laser stacks up to 300A. The LDC1000 includes a 300W or 600W thermoelectric cooler controller to drive suitable heat sinks.

Intuitive User-Friendly Interface

An internal microprocessor provides the flexibility and convenience of software control and the system status is presented on an easy-to-read LCD graphics display. Control of the Model LDC1000 can be achieved from the front panel or remotely via an RS-232 interface.

Built-In Laser Diode Protection Features

The LDC1000 features advanced circuitry to protect both the diode and the controller. Safety features include transient suppression, a suitable mains filter, delayed output enable, hardware interlock and a relay closure shorts the laser output when power to the LDC1000 is turned off. An additional feature is if the laser temperature departs from a user defined temperature window, the laser current is switched off automatically.

Error Indication

In any case of error, such as exceeding the customer set limits, the diode current is turned off immediately and an error message appears on the display.

Laser Diode Current Modulation

External inputs allow analogue modulations and external triggering. An internal pulse generator allows digital modulation. The maximum modulation frequency of the laser diode current is 100Hz. As a safety feature, the laser current limit can not be exceeded during external modulation.

Pilot Laser Control

If a high power laser diode is provided with a pilot laser, it can be controlled by the LDC1000. The pilot laser can be switched on and off and its optical power intencity can be set

Power Monitor

If a high power laser diode is provided with a power monitor diode, which deliver a voltage corresponding the optical power it will be shown at the display and can be used for calibrating the LDC1000 P/I characteristic line.

Quasi Power Setting / Monitoring

Because the laser driver is current controlled, the laser power cannot be controlled directly. But the user can set two calibration points at the P/I characteristic line and the LDC1000 calculates the set power into set current and measured current into actual power. So the user can choose to set the laser current or set the laser power and can read the actual current and the actual power from display.

Supported Temperature Sensors

The LDC1000 can work with three several temperature sensor types: NTC, PT100, PT1000.

Adaptability to Different Heat Sinks

The LDC1000 can easily adapted to different heat sinks by the software PID controller. An adjustable TEC current limit prevents the controller from overdriving the TEC element. The LDC1000 includes a 300W or 600W thermoelectric cooler controller. Our heat sinks COOL30 and COOL50 are suitable for cooling 30W and 50W (optical power) laser diodes. They need the 300W TEC driver. Our heat sink COOL100 is suitable for cooling a 100W (optical power) laser diode and needs the 600W TEC driver.

Fan Power Control

Normaly the heat sink is provided with a powerfull fan. In most cases the full fan power will not be used. For that reason the fan voltage can varied between 6 .. 12V.

Contact Form

Do you have questions regarding our products or applications?

Contact us via our contact form and we will get back to you as soon as possible.

Kontaktformular Detailseite EN

"*" indicates required fields